I apologize fir this long winded response, but to answer your question in lay-terms is a bit long-winded.

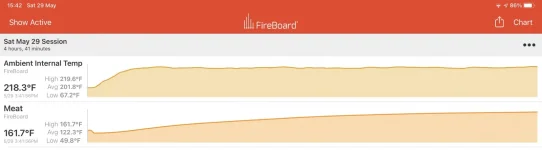

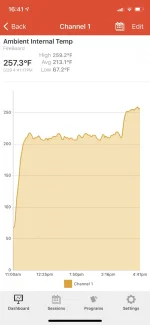

With PID controllers the feedback signal (the permanent ambient air probe) sends a signal to the controller that is compared to the set point you select. Hence, within a given bandwidth (temperature range) the ambient grill probe does not show variation by design, but will do so if it goes out of the designed tolerance (bandwidth). Hence the reported grill temperature appears to hold steady while using a separate probe, without that controller dampening, will show actual variations within its individual design tolerance or accuracy.

Why does this happen?

First, PID controllers are designed to iteratively “learn” and constantly adjust feed, and airflow to approximate match a set point., largely the job of the “I” function.

Second, but minor variations are typically tolerated and counteracted by the “D” function, something we used to call the “Do, Don’t Do Function”. This is because small variations have no discernible impact on production (cooking the food) over time. Essentially that “D” function keeps the controller from constantly chasing itself and over or under feeding within a programmed “tolerable” bandwidth.

Third, a pellet grill/smoker is dealing with a solid fuel that has a natural lag time between sensing the actual grill temperature, comparing it to set point, calling for more or less heat, adjusting the pellet feed, waiting for ignition, and sensing the resulting heat output change via the grill probe. Note that this lag is not as much of a case with liquid ignition control systems like cruise control on an automobile for example which has a much closer correlation and timing between wheels sensors and fuel feed to the engine.

Fourth, in smoking and cooking a 10-30 degree temperature variation has very little real impact on the final product...your dinner. [By the way, the same happens with your oven to a lesser extent as you seldom, if ever, see the actual temperature of the oven, unless you are using a separate probe]. This is not the case with industrial control applications where tolerances are much tighter as the product requires.

Fifth, it keeps the operator (the cook) from constantly adjusting and fiddling with the controls; something that would happen if every degree in temperature variance from set point were shown.

I use a separate Weber ambient air probe connected to port #4 every time I cook and have learned to rely on it to monitor what is actually going on in the grill. I also have a separate Maverick probe unit and instant read thermal pens. However, I seldom need to make adjustments on my ex4 as I consider most variances within tolerance.

But even without that or your other probes, you can observe PID bandwidth override by letting your unit stabilize at a given temperature and then adjusting the temperature upward or downward by 5 or 10 degrees and noting how, almost instantaneously it reports that set point has been achieved. But if you change by 40 or 50 degrees it takes a while to report that set point has been achieved,

Again, sorry for the long post and what, undoubtedly is TMI